Twelve hundred new shelters

In 1988 Moshé Zwarts and Rein Jansma were commissioned by the municipality of The Hague, along with the Haagse Tramweg Maatschappij, the city’s public transport company, to design twelve hundred tram and bus shelters for The Hague and its suburbs. The result, which dates from the prehistory of architectural studio ZJA (founded in 1990), has as its most important feature a design that was extremely light and transparent for its time, with a flexible and modular character, suitable for several different types of shelter in a variety of sizes. In 1989 it was awarded the Berlage Prize.

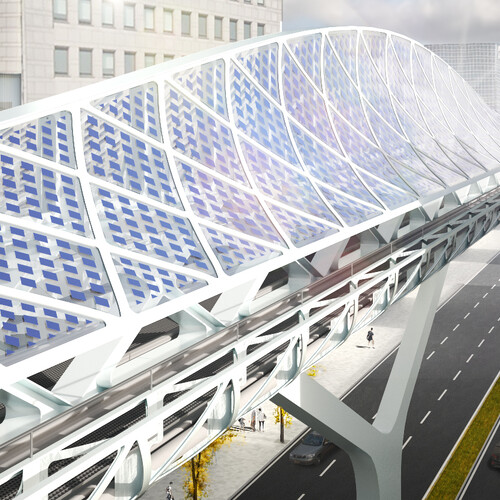

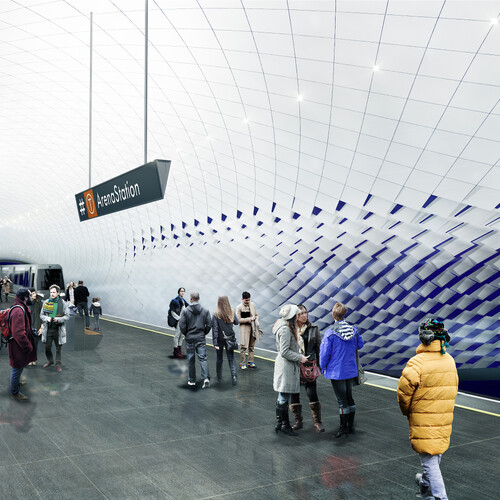

Distinctive, light and safe

Twelve hundred tram shelters and thirteen kilometres of railings, with a distinctive light and transparent design, represented a considerable innovation in the late 1980s. No more sturdy boxes with solid walls but glass and plastic shelters that increased visibility and thereby the safety of passengers. It was a pioneering design in the Netherlands, especially because of its application of toughened glass. It is also low-maintenance, since rainwater drains through the vertical sections, which also house the cables for the lighting. In all its various manifestations and with its bright and unassuming design, the shelter remains a characteristic element of the street furniture of The Hague.

Construction kit of sections and castings

The design is a construction kit based on a principle used for all parts of the shelter, including the surrounding railings, and for the tram stop poles themselves and the information boards. The shelters need to fit into the most diverse surroundings, and their size and shape (narrow, broad, deep and long) varies a great deal. The construction system consists of standard triangular sections that are made up of press-braked components. These are the basic elements, both horizontally and vertically. The glass walls and plastic roofs are attached to them.

A set of castings was designed for the connections between the main structural elements and the glass walls, seats, handrails and advertising boards: steel to connect the horizontal and vertical sections, and aluminium to connect the glass walls to the structure.

Awards

Winner: Dutch Steel Award 1990, Berlageprijs 1989

Client: the municipality of The Hague, along with the Haagse Tramweg Maatschappij

Architect: ZJA

Year: 1988

Project: #376